+886 916 076 098

About Us

About Us

-

SMKS Precision Machinery Co., Ltd. specializes in the research, development, and manufacturing of fluid polishing equipment. Our range of fluid polishing machines offers effective solutions for internal hole polishing, cross-hole deburring, and micro-hole finishing across various industries.

Our equipment is widely used for applications such as inner wall polishing of small holes, gear deburring, edge deburring, curved hole polishing, gear surface finishing, impeller polishing, and channel polishing.

-

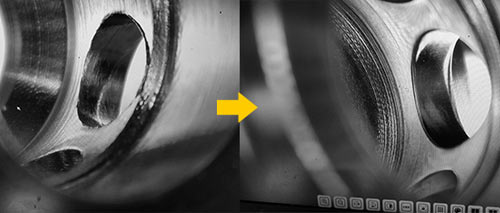

SMKS fluid polishing technology utilizes polymer-based soft abrasives that are extruded through the internal holes or target surfaces of workpieces. Through repeated abrasive flow cycles, the process achieves high-precision polishing and effective deburring.

This advanced polishing method is widely applied across various industries, including automotive (especially for critical engine components), aerospace, defense manufacturing, 3D printing, medical devices, mold making, textile machinery, transmission gears, and electronic components.

Technical Description

-

Fluid abrasive finishing technology uses specially formulated abrasive media as the grinding medium. Through controlled extrusion, the abrasive media flows repeatedly through internal passages or across the surfaces of workpieces, achieving precise polishing and effective deburring.

-

This technology has been widely adopted in industries such as automotive, aerospace, mold manufacturing, hydraulics, medical devices, electronics, power transmission, and textiles. It enhances fuel system efficiency, reduces friction and wear in transmission components, lowers operational noise, improves turbine performance by eliminating surface stress, and increases mold interior surface smoothness while reducing demolding force.

-

At the same time, we offer customized solutions and equipment tailored to your specific product requirements, ensuring optimal performance and quality.

Products: Polishing Equipment

Abrasive Flow Polishing Machine

Our Abrasive Flow Polishing Machine adopts specially engineered fluid abrasive media as the grinding medium. Through a precision-controlled extrusion process, the media flows unidirectionally—entering the component from one end and exiting from the other—achieving consistent internal surface polishing and efficient deburring.

This advanced technology is highly versatile and well-suited for polishing curved flow channels as well as removing burrs from complex intersecting holes.

We offer fully customizable solutions and equipment configurations tailored to meet the unique specifications and performance requirements of your products.

Micro-Hole Abrasive Flow Polishing Machine

The SMKS Micro-Hole Polishing Machine offers real-time online flow monitoring, with flow rates precisely controlled within a margin of a few thousandths.

This system utilizes low-viscosity polishing media containing ultra-fine abrasives specifically designed for micro-hole applications. Through controlled extrusion, the media is forced through the internal surfaces of micro-holes, performing rapid and precise finishing.

Once the component reaches the target flow rate—indicating the desired surface finish—the integrated flow monitoring system immediately halts the polishing process, ensuring optimal consistency and efficiency.

This machine is ideally suited for polishing precision micro-holes in nozzles, valve components, injector plates, and other critical parts requiring ultra-fine internal surface finishing.

Mirror Surface Polishing Machine

The SMKS Mirror-Finish Polishing Machine employs ultra-fine, specialized elastic abrasives that are directly sprayed onto the surface of the workpiece, performing a gentle sliding abrasion process. This results in high-precision polishing, burr removal, edge rounding, oxide layer removal, and surface mark elimination.

The system is especially suitable for precision finishing of irregular surfaces such as curved profiles, gear teeth, grooves, and textured or contoured surfaces, with material removal typically limited to just 1–2 μm.

This technology delivers exceptional mirror finishes on the external surfaces of complex-shaped parts and can reduce surface roughness by 1 to 2 grades. It is widely used in applications such as tool edge honing, punch polishing, precision medical instrument finishing, coating mark removal, and engraving mold polishing.

The machine is equipped with a fully enclosed, eco-friendly polishing system that ensures consistent surface results. The elastic abrasive media complies with environmental standards and does not chemically bond with metal surfaces, making it a clean, efficient, and convenient surface finishing solution.

High-Speed Abrasive Flow Deburring Machine

The High-Speed Abrasive Flow Deburring Machine utilizes liquid abrasive media pressurized through a high-performance intensification system. This significantly enhances the cutting force applied to burrs on the workpiece, enabling rapid and efficient deburring through high-speed abrasive extrusion and flow.

Key process parameters—including media pressure, angle, and operation time—are precisely controlled via a PLC system to ensure consistent surface finishing and controlled adjustment of surface roughness. The process leaves no abrasive residue on the workpiece, ensuring a high level of safety, cleanliness, and efficiency.

This equipment is ideal for deburring the outer surfaces of irregularly shaped metal parts. To ensure optimal material removal, abrasive media with a hardness greater than the workpiece material should be selected. This allows the abrasives to effectively cut and finish softer materials during processing.

In addition, the abrasive particles must maintain chemical stability in the slurry to avoid undesired reactions during machining. Within a certain range, increasing the concentration of the liquid abrasive media boosts the number of active abrasive particles per unit area, thereby increasing the material removal rate.

Abrasive Media

As the core abrasive medium used in fluid polishing machines, SMKS fluid abrasive media is composed of high-performance silicon carbide micropowder or diamond micropowder, with hardness reaching up to 10,000 kg/mm² and particle sizes as fine as W0.5.

The media is environmentally friendly—free from pollutants, corrosive substances, hazardous chemicals, or any materials harmful to health or the environment. It complies with modern standards for clean and sustainable manufacturing.

For applications requiring higher cutting efficiency, boron carbide–based fluid abrasive media is also available. With a hardness greater than that of conventional silicon carbide, it enables faster material removal and is especially suited for hard-to-machine materials such as hardened tool steels, cobalt alloys, and other high-strength metals.