+886 916 076 098

Abrasive Flow Polishing Machine

B600Bidirectional Abrasive Flow Polishing Machine

Product Features

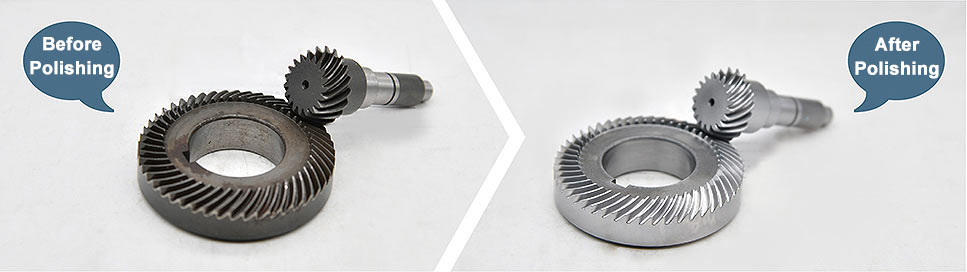

This fluid polishing machine utilizes a specially formulated abrasive media as the grinding agent. Through applied pressure, the media flows back and forth within internal holes or across part surfaces, performing repeated grinding to achieve both polishing and deburring.

It is highly versatile and suitable for a wide range of applications, including mold polishing, gear finishing, and deburring of small components.

Working Principle

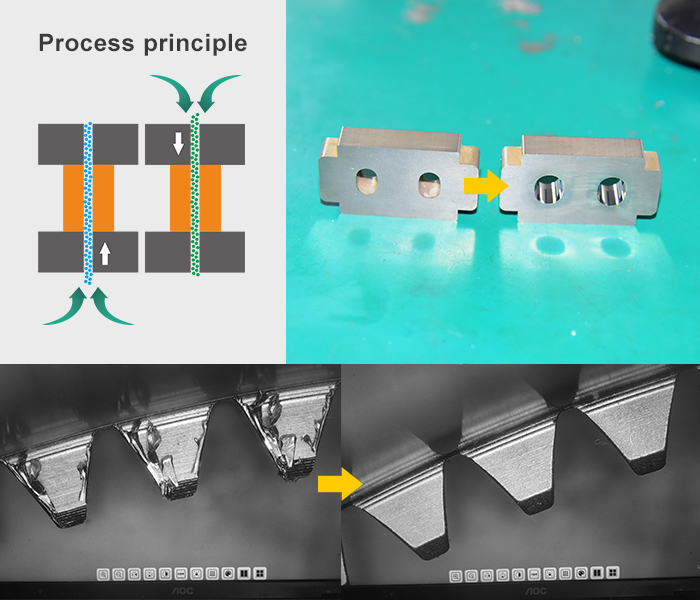

This technology operates by applying pressure through upper and lower hydraulic cylinders, forcing a soft abrasive media to flow through machined surfaces, internal holes, or edge corners. This process enables effective deburring, chamfering, and polishing.

Through a controlled reciprocating motion, the system can achieve high-precision mirror finishing. It is especially suitable for complex geometries such as contoured surfaces and curved internal channels—areas that are typically inaccessible to traditional cutting tools.

This method is particularly effective for polishing the inner surfaces of fluid-conducting channels in gas or liquid systems, where it aligns the abrasive marks with the direction of flow. This not only improves the surface finish and performance of molds or workpieces but also extends their service life.

The process can achieve ultra-smooth surface roughness levels of Ra 0.025 to Ra 0.015 µm, reaching true mirror-grade finishes.

Machine Specifications:

- Height: 2150 mm / Width: 1310 mm

- Depth: 1030 mm / Weight: 1.6 tons

- Worktable Width: 1100 mm

- Fixture Operating Height: 300 mm

- Fixture Operating Width: 700 mm

- Media Cylinder Diameter: Ø152 mm

- Abrasive Media Capacity per Fill: 6 kg

- Control Panel: Touch screen

- Electrical Control System: PLC

- Processing Pressure (Adjustable): 1~14 MPa

- Power Consumption: 5 HP

- Power Supply: 3-phase 220V / 60Hz & 380V / 50Hz