+886 916 076 098

Abrasive Flow Polishing Machine

B800 Bidirectional Abrasive Flow Polishing Machine

Product Features

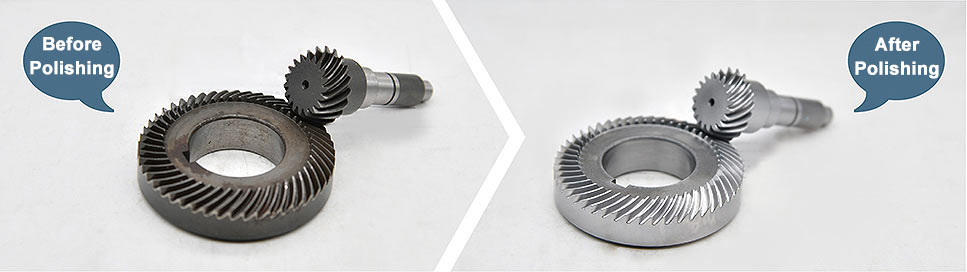

This fluid polishing machine uses a specially formulated abrasive media as the grinding medium. By applying pressure, the abrasive flows back and forth through internal holes or across the surfaces of parts, repeatedly grinding to achieve polishing and deburring.

The machine offers a wide range of applications, including mold polishing, gear finishing, and deburring of small components, among others.

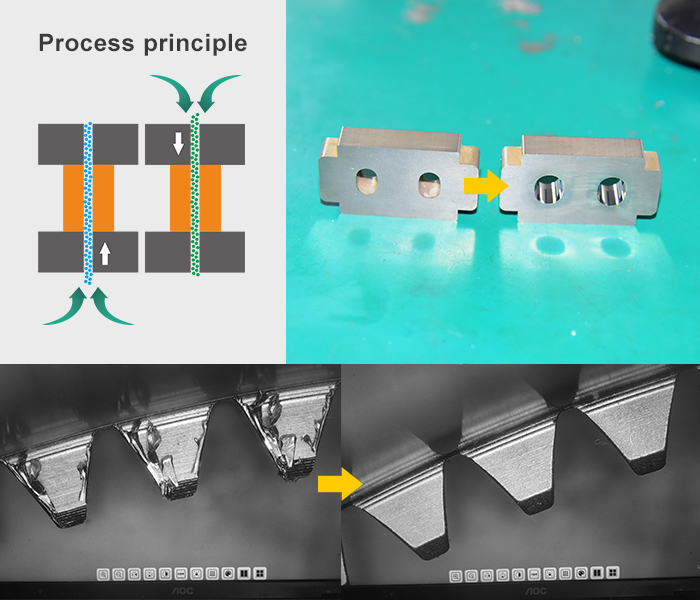

Working Principle

This technology utilizes a vertical hydraulic system that applies pressure from both the upper and lower cylinders to force soft abrasive media through the machined surfaces, internal holes, or edge corners. This process enables deburring, chamfering, and polishing through a controlled reciprocating motion

It is especially suitable for complex geometries such as contoured surfaces and curved internal passages—areas typically inaccessible to traditional tools.

In particular, this method is ideal for mirror polishing of internal flow channels in gas or liquid systems, where the abrasive flow aligns with the direction of fluid movement. This not only improves the surface finish and functionality of the mold or workpiece but also enhances overall performance.

The final surface roughness can reach as low as Ra 0.025 to Ra 0.015 µm, achieving a true mirror finish and significantly extending the service life of the component.

Machine Specifications:

- Height: 2550 mm / Width: 3200 mm

- Depth: 1400 mm / Weight: 2.8 tons

- Worktable Width: 1150 mm

- Fixture Operating Height: 400 mm

- Fixture Operating Width: 850 mm Media

- Cylinder Diameter: Ø252 mm

- Abrasive Media Capacity per Fill: 25 kg

- Control Panel: Touch screen

- Electrical Control System: PLC Processing

- Pressure (Adjustable): 1~18 MPa

- Power Consumption: 10 HP

- Power Supply: 3-phase 220V / 60Hz & 380V / 50Hz