+886 916 076 098

Abrasive Flow Deburring Machine

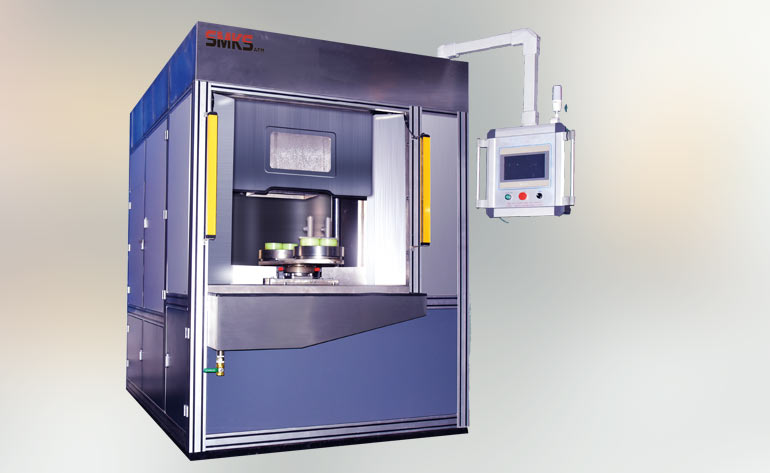

SMKS-XF608

Product Features

Taiwan SMKS Precision Machinery Co., Ltd. specializes in manufacturing polishing equipment, including fluid polishing machines, internal hole polishing machines, fluid deburring equipment, and extrusion grinding machines. Our solutions focus on challenging tasks such as micro-hole polishing, internal hole polishing, and deburring of intersecting holes.

Our polishing equipment is widely applied in deburring internal holes, micro-holes, gears, valve bodies, pump bodies, polishing pipe interiors, 3D printed parts, blades and impellers, as well as mold polishing.

Working Principle

The high-speed abrasive fluid deburring machine utilizes liquid abrasive media, which is pressurized through a boosting system to increase the grinding force on workpiece burrs. The rapid extrusion and grinding action of the liquid abrasive media achieves fast and efficient deburring.

PLC controls key parameters such as abrasive pressure, angle, and processing time to quantitatively improve the surface roughness of the workpiece. This technology leaves no abrasive residue on the workpiece, ensuring high efficiency, safety, and easy cleaning.

This equipment is suitable for rapid deburring of irregular metal workpiece external surfaces. When selecting abrasives, it is important to choose materials with hardness higher than that of the workpiece to effectively cut and process the surface of softer materials.

Additionally, the abrasive particles must maintain chemical stability in the grinding fluid to prevent adverse chemical reactions during processing.

Within certain limits, a higher concentration of liquid abrasive media increases the number of abrasive particles interacting with the workpiece surface per unit area and time, thereby enhancing the material removal rate.

Machine Specifications:

- Height: 2000 mm / Width: 1600 mm

- Depth: 2000 mm / Weight: 1.8 tons

- Worktable Width: Equipped with dedicated operator platform and workstation customized per product requirements

- Fixture Operating Height: 350 mm

- Fixture Operating Width: Customized per product requirements

- Media Cylinder Diameter: Ø250 mm

- Abrasive Media Capacity per Fill: 3 kg

- Media Cylinder Volume: 10.0 inch-liters

- Control Panel: Touch screen

- Electrical Control System: PLC

- Processing Pressure (Adjustable): 1–12 MPa

- Power Consumption: 5 HP

- Power Supply: 3-phase 220V / 60Hz & 380V / 50Hz