+886 916 076 098

Abrasive Flow Polishing Machine

B801 Unidirectional Abrasive Flow Polishing Machine

Product Features

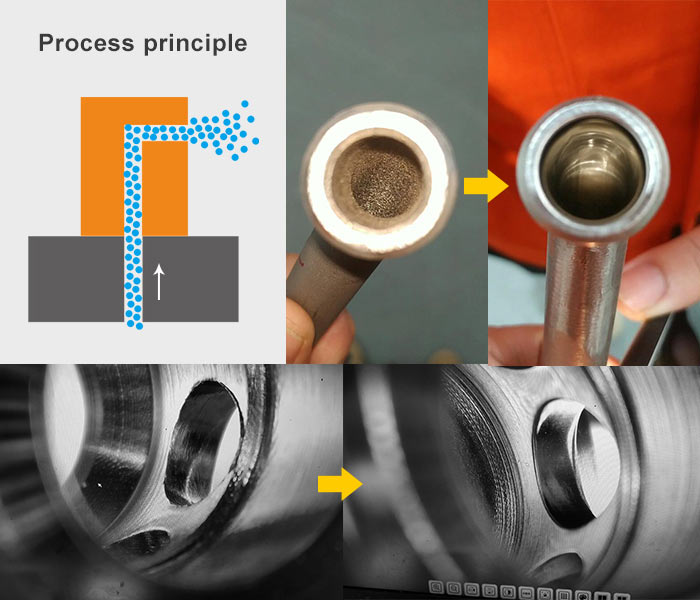

This fluid polishing machine utilizes a specially formulated abrasive media as the grinding medium. Under pressure, the media flows in a single direction—entering from one end of the part and exiting from the other—to achieve efficient polishing and deburring.

It is widely applicable for various tasks, including polishing of curved flow channels and deburring of intersecting or cross-drilled holes.

We also offer customized solutions and equipment tailored to your specific product requirements, ensuring the process meets your technical standards and production needs.

Working Principle

This innovative fluid polishing machine is specifically developed for irregular workpieces such as plastic molds, hot nozzles, hot runners, long tubes, and bent pipes. It features automated operation through PLC control, enabling efficient, cost-effective, and high-precision polishing.

The polishing marks are aligned with the functional direction of the workpiece, offering consistent and directional surface finishing. This process is particularly well-suited for complex shapes such as contoured surfaces, curved channels, multi-holes, micro-holes, and long or irregular holes—areas typically inaccessible to traditional tools.

To meet customer-specific needs, we provide customized unidirectional abrasive flow polishing machines and services. Additionally, we offer subcontract services including flow channel system finishing, cavity and micro-hole repair, and internal polishing and deburring for micro, multi, long, or irregular holes.

This advanced process can improve the precision of a part by up to three grades in just a few minutes, achieving a surface roughness as low as Ra < 0.015 μm.

Machine Specifications:

- Height: 2570 mm / Width: 1500 mm

- Depth: 1700 mm / Weight: 3.3 tons

- Worktable Width: Equipped with a dedicated operator platform and workstation based on product requirements

- Fixture Operating Height: Customized according to product requirements

- Fixture Operating Width: Customized according to product requirements

- Media Cylinder Diameter: Ø252 mm

- Abrasive Media Capacity per Fill: 50 kg

- Control Panel: Touch screen

- Electrical Control System: PLC

- Processing Pressure (Adjustable): 1–14 MPa

- Power Consumption: 10 HP

- Power Supply: 3-phase 220V / 60Hz & 380V / 50Hz