+886 916 076 098

Micro-Hole Abrasive Flow Polishing Machine

SMKS-602

Product Features

The SMKS micro-hole abrasive fluid polishing machine features real-time online flow control, maintaining flow stability within a thousandth range. It utilizes low-viscosity abrasive media with extremely fine particles specifically designed for micro-holes. Through a squeezing motion, the abrasive fluid passes over the inner surfaces of micro-holes, performing rapid and precise polishing.

When the micro-hole workpiece reaches the predetermined flow target, the machine’s flow monitoring system sends a signal to immediately stop the polishing process.

This equipment is ideal for polishing, chamfering, and deburring micro-holes in components such as nozzles, valve assemblies, and jet perforated plates.

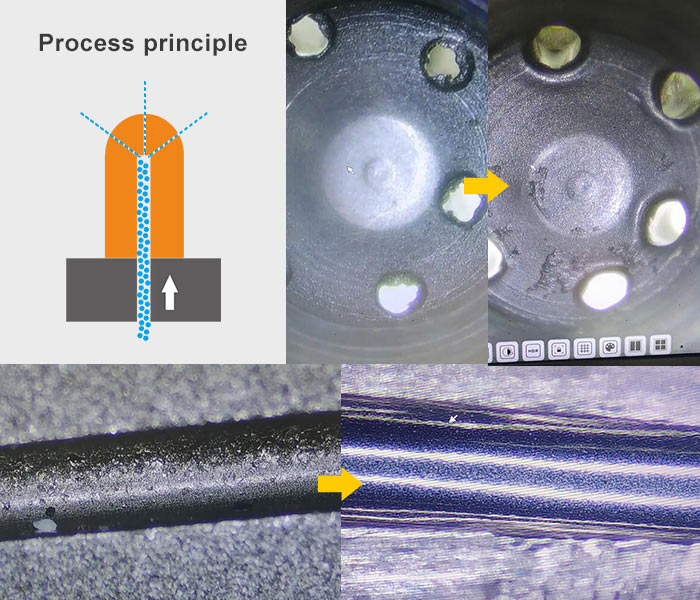

Working Principle

The principle of micro-hole abrasive fluid polishing is essentially similar to that of our unidirectional flow polishing machine. The main difference lies in the use of a low-viscosity medium combined with finer abrasive particles, resulting in lighter abrasive media with stronger fluidity and more uniform polishing effects.

This allows the abrasive media to flow through small or aged micro-holes to remove minute burrs, thereby improving the surface quality of pressure chambers and micro-hole inner walls.

This type of abrasive fluid polishing machine is specially developed for fuel oil atomizer nozzles and hydraulic valve components.

The technology enhances fuel atomization, improves engine performance, and reduces emissions.

It can increase part precision by up to three grades within minutes, achieving a surface roughness of Ra < 0.015 μm.

The micro-hole abrasive fluid polishing machine stands out in the fuel injection industry. It performs complex calculations based on the relationships between pressure, abrasive viscosity, abrasive temperature, and other parameters.

When processing fuel injectors, you only need to set the corresponding values, and once the machine reaches the preset parameters, it automatically stops polishing.

The processing time ranges from 10 to 20 seconds, with flow rate deviation controlled within ±0.1%.

Additionally, the machine can be integrated with flow measurement instruments and high-pressure cleaning equipment. These systems can be configured according to customer requirements for single or multiple workstation setups.

Machine Specifications:

- Height: 2000 mm / Width: 800 mm

- Depth: 1800 mm / Weight: 1.5 tons

- Worktable Width: Equipped with dedicated operator platform and workstation customized per product requirements

- Fixture Operating Height: 200 mm

- Fixture Operating Width: Customized per product requirements

- Media Cylinder Diameter: Ø80 mm

- Abrasive Media Capacity per Fill: 3 kg

- Media Cylinder Volume: 10.0 inch-liters

- Control Panel: Touch screen

- Electrical Control System: PLC

- Processing Pressure (Adjustable): 1–12 MPa

- Power Consumption: 5 HP

- Power Supply: 3-phase 220V / 60Hz & 380V / 50Hz